Post by Zuama on Nov 1, 2021 19:46:20 GMT

For the sake of simplicity, there are 2 types of rubber, Natural and Synthetic.

1. Natural Rubber

Natural rubber is harvested from rubber trees, which are a family of trees that belong to the family Euphorbiace. Natural rubber is extracted by method called tapping, by making incisions into the bark and collecting the fluid into vessels attached to the rubber trees. The liquid is a sticky, milky sap called latex, and requires a couple of steps before it will be sold as natural rubber.

Tapping process

Once the latex is collected from the plantation, is rushed to the processing plant, which prevents the latex from coagulating naturally and rendering the latex useless. At the processing plant near the plantation, the latex is heated and mixed with acid ammonia which forms rubber like curds; sulfur can be added to create a harder and more stable mixture. Much like making cheese, the rubber curds float to the surface of the liquid and is skimmed off the top and run through heavy rollers to remove excess water. The sheets of natural rubber that are formed are cut and stacked ready for shipment to rubber molders.

![]()

Rubber molder

2. Synthetic Rubber

Synthetic rubber manufacturing proccess

To make things short, the difference between those two type are. natural rubber has higher tensile strength, higher tear resistance, and low odor compared to synthetic rubber. Synthetic rubber have better chemical resistances, fluid resistances, ozone resistances, electrical resistances, and more. In addition, synthetic rubbers can have excellent heat resistance, lower temperature resistance, and heat aging improvements compared to the nature rubber.

Difference was quite big. However, things become twisted and mixed as we get into products, as both type can be made into the same product.

To make things a bit simple, i'll divide each type products based on it's complexity and building cost. Or to make it more simple, let's just called this CHEAP VS EXPENSIVE

Natural products: Rubber band, rubber duck, baby dot, dog's rubber bone (toy industry?), rubber glove, rubber boots, and animal mat.

"Mightymoo Mat"

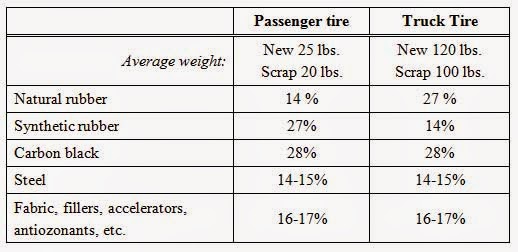

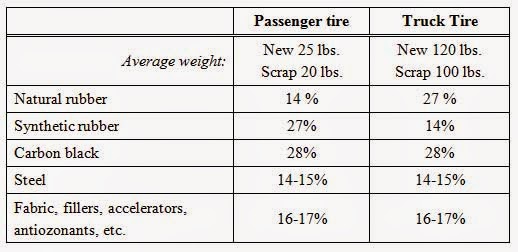

Synthetic products: Car tire, tracktor tire, electrical cable (would be nice if you add copper), rubber door seal, rubber steering wheel, etc.

Building

We only need one building, rubber plant. Why? Phase 1 Natural rubber can be made in plantation, and for the synthetic, was extracted from crude oil. Phase 1 was oil rig, and phase 2 was refinery, phase 3? rubber plant. See?

"Crude oil is the principal raw material in synthetic rubber. Approximately 70% of all rubber used today is synthetic."

"Over time, man learned how to make the majority of rubber used from hydrocarbons and sulfur. As the hydrocarbons can come mostly from crude oil, you could say that man made rubber is dependent on crude oil stocks for its raw materials."

1. Natural Rubber

Natural rubber is harvested from rubber trees, which are a family of trees that belong to the family Euphorbiace. Natural rubber is extracted by method called tapping, by making incisions into the bark and collecting the fluid into vessels attached to the rubber trees. The liquid is a sticky, milky sap called latex, and requires a couple of steps before it will be sold as natural rubber.

Tapping process

Once the latex is collected from the plantation, is rushed to the processing plant, which prevents the latex from coagulating naturally and rendering the latex useless. At the processing plant near the plantation, the latex is heated and mixed with acid ammonia which forms rubber like curds; sulfur can be added to create a harder and more stable mixture. Much like making cheese, the rubber curds float to the surface of the liquid and is skimmed off the top and run through heavy rollers to remove excess water. The sheets of natural rubber that are formed are cut and stacked ready for shipment to rubber molders.

Rubber molder

2. Synthetic Rubber

Synthetic rubber manufacturing proccess

To make things short, the difference between those two type are. natural rubber has higher tensile strength, higher tear resistance, and low odor compared to synthetic rubber. Synthetic rubber have better chemical resistances, fluid resistances, ozone resistances, electrical resistances, and more. In addition, synthetic rubbers can have excellent heat resistance, lower temperature resistance, and heat aging improvements compared to the nature rubber.

Difference was quite big. However, things become twisted and mixed as we get into products, as both type can be made into the same product.

To make things a bit simple, i'll divide each type products based on it's complexity and building cost. Or to make it more simple, let's just called this CHEAP VS EXPENSIVE

Natural products: Rubber band, rubber duck, baby dot, dog's rubber bone (toy industry?), rubber glove, rubber boots, and animal mat.

"Mightymoo Mat"

Synthetic products: Car tire, tracktor tire, electrical cable (would be nice if you add copper), rubber door seal, rubber steering wheel, etc.

Building

We only need one building, rubber plant. Why? Phase 1 Natural rubber can be made in plantation, and for the synthetic, was extracted from crude oil. Phase 1 was oil rig, and phase 2 was refinery, phase 3? rubber plant. See?

"Crude oil is the principal raw material in synthetic rubber. Approximately 70% of all rubber used today is synthetic."

"Over time, man learned how to make the majority of rubber used from hydrocarbons and sulfur. As the hydrocarbons can come mostly from crude oil, you could say that man made rubber is dependent on crude oil stocks for its raw materials."

[RMH]